- Articles

- FAQ - frequently asked questions

FAQ - frequently asked questions

Our customers are wondering:

What is special about Marnar Bruk Royal?

We use pine materials that are first pressure impregnated (CU) and then boiled in a linseed oil-based solution. This results in a stable material with a long service life. Marnar Bruk Royal is available in seven different colours.

Where can we order Marnar Bruk Royal?

You can get it from most builders' merchants. If they don't have it in stock, they can order it for you. Find your nearest retailer here.

Is Marnar Bruk Royal maintenance free?

We call it maintenance-friendly. Only general cleaning and cosmetic refreshing is required.

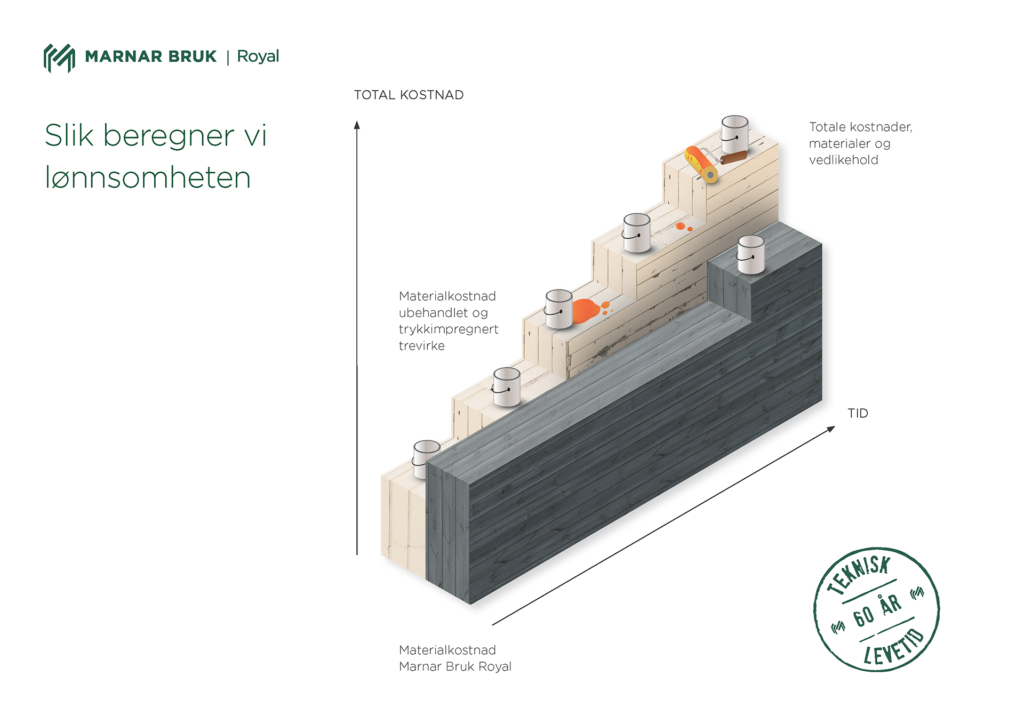

Is it more expensive than other materials?

It is somewhat more expensive to buy than e.g. primed or ordinary impregnated, but remember that Marnar Bruk Royal is finished on the facade and terrace. You avoid the costs of painting/staining. This makes it a profitable choice. Royal is more affordable than other similar products.

How long does the colour last?

This depends entirely on how much stress the wood is exposed to and which colour you choose. Terraces and other smooth planed surfaces require more frequent refreshing. We also have RO.0 Weather Grey, which is without colour pigment and will turn grey naturally.

How will the colours play out?

Marnar Bruk Royal has transparent colours where the wood structure should be visible. The colour can therefore vary from one table to another, creating a nice play on the facade or terrace. If you want something more opaque, you should consider a painted product.

Which fasteners should you use?

Whether you want to use nails or screws is up to you, but we recommend A2 stainless steel or A4 acid-proof fasteners.

The cladding has become covered in resin/white and brown knots. Is this normal?

Resin is a natural part of the wood, but is an important factor in the quality and longevity of the materials. Resin rashes may occur for periods, but will usually disappear again. The weather will have a major impact on this. Alternatively, this must be scraped off.

What is the lifespan of Marnar Bruk Royal?

Technical lifetime is 60 years. Ref our EPD.

Is Marnar Bruk Royal an environmentally friendly product?

Marnar Bruk Royal is an approved ECO product. It is the only method that assesses the building product's actual environmental properties based on a third-party verified Environmental Product Declaration (EPD). The ECO product is equivalent to the Nordic Swan Ecolabel in Breeam NOR projects (certification of sustainable buildings).

Where does the raw material come from?

The raw material comes from our own sawmill Byglandsfjord Sag or other PEFC-approved suppliers in Norway and Sweden. Marnar Bruk AS is 100% PEFC certified.

Do the cut surfaces need to be treated?

We recommend that you lubricate the cut surfaces with royal oil or similar to prevent water ingress into the wood and preserve the cosmetic appearance. You can order this together with the materials.

How much space should the decking be installed with?

The recommended installation gap for decking is approx. 1-3 mm between each board, as a Royal board will move less than other impregnated wood. Also remember that grooves should always be installed with the groove side up.

Is Marnar Bruk Royal cladding approved?

The simple answer here is: Yes, cladding from Marnar Bruk Royal is approved. Marnar Bruk Royal is classified in fire class E, and can be used on most wooden buildings. For smaller projects, run an analysis of your building via the digital tool Branntrygg.no. In the case of a larger project where a fire concept needs to be drawn up, the fire consultant will incorporate this into the concept.

Below you will find some important points regarding Fire Safe:

- Surface cladding is basically a small deviation in a fire concept

- Fireproof is a standardised and pre-documented failure analysis

- Branntrygg can be used by organisations that are centrally approved in action classes 1 and 2,

on buildings in fire classes 1 and 2, risk classes 2, 3, 4 and 6. - The tool can be found at Branntrygg.no

What is Marnar Bruk Royal?

In simple terms, Marnar Bruk Royal is wood that is manufactured to withstand the harsh Nordic climate. The process itself consists of two stages where we first pressure impregnate pine raw material. Here, impregnating salts, which protect against fungi and insects, are pressed right into the heartwood under pressure. Once the wood has been pressure impregnated, the oiling process can begin. The wood is then moved to a vacuum tank that is filled with hot oil. The vacuum in the tank reduces the boiling point of the water to around 60 degrees. This causes the water to be drawn out of the wood, and the cells in the wood are replaced with oil. The oil fills the pores in the wood and is pressed 1-3 mm into the surface of the wood, and up to 15-20 mm into the end grain. The process ends with the oil being pumped out of the tank and the materials being dried in a vacuum. This gives the wood extreme rot protection, leads to more stable timber and a long service life.

What is Royal oil?

Royal oil consists of linseed oil with or without pigment. Royal oil fills the pores in the wood and is pressed 1-3 mm into the surface of the wood and up to 15-20 mm into the end grain. Royal oil comes in 6 different colours, where the colour we call "Weather Grey" is without pigments and will turn grey naturally through weather and wind.

How do I apply Royal oil?

We recommend using Marnar Bruks maintenance oil, which comes in all the colours we offer. This is the same oil that we use in our own royal production. For cosmetic reasons, you can refresh the pigment based on your own aesthetic expectations. When this is done, new oil is also added to the surface, which in turn helps to maintain the quality. If you do not choose to maintain for cosmetic reasons, you should - to replace oil that leaches out through weather and wear and tear - apply one coat of Royal oil sometime between 5-30 years after installation. The time interval here will depend on how exposed the surface is to the weather. New oil is applied as another type of surface treatment; use a broom, roller or sprayer.

How many running metres per square metre on a terrace?

You need to calculate 8.2 running metres per square metre.

What is Royal cladding?

Marnar Bruk | Royal cladding is produced from planed pine wood with an unplaned front, and is available in many different variants and profiles. In addition to being pressure impregnated with a CU-based water-soluble salt impregnation, the cladding is boiled in a royal oil under vacuum. This treatment provides a virtually water-repellent surface as the oil penetrates into the cells of the wood and reduces moisture migration in the wood. This results in increased dimensional stability, less moisture movement, extreme rot protection and a long service life.

Why choose Royal impregnated products?

First and foremost because Royal is manufactured with a long service life in our harsh Nordic climate in mind. Royal is pre-treated on delivery; ready for installation and use, no top coat required. The treatment reduces moisture absorption, resulting in a more stable wood. Extreme rot protection, long service life and several different colours to choose from.

Are you allowed to change the cladding yourself?

We recommend using authorised craftsmen, as they have first-hand knowledge of what is required - and, not least, are skilled in their trade. Replacing the cladding requires some equipment and may also require some documentation.

How to wash a Royal-treated terrace?

Decking should be washed at least once a year, preferably in the spring, to remove dirt, surface fungi and any colour pigments that may have come loose on the surface. Dirt is easily removed with light rinsing using a garden hose and without the use of chemicals. Surface mould is removed by washing, and a fungicide is applied before any new oil with or without pigments is applied.

Can I treat Royal with other surface products?

Royal can be treated with other surface products if you want a different colour than the original Royal colours, but this should not be done until the wood has been installed for at least one year. This is to avoid bleeding through of copper material from the impregnation. It is recommended to apply a primer coat and leave it for a few months before applying the top coat. Pine is rich in resin, and resin bleed-through from knots can occur and become visible, especially on light paint colours. If you choose to use surface products other than Royal oil on the wood, you will change the properties of the product, which means that the warranty and maintenance intervals recommended for Royal products will no longer apply.

Can you use Royal products inside?

Royal products are intended for exterior use only. The product should not be used indoors as it may emit odours. It is not dangerous, but the odour will remain in the tables for some time - especially indoors.